Cotton t-shirt manufacturing is one of the most in-demand processes in the global fashion industry. From small boutique brands to large-scale apparel companies, cotton t-shirts are a staple product because of their comfort, durability, and universal appeal. By mastering cotton t-shirt manufacturing, you can create premium quality garments that customers love and keep coming back for. This ultimate guide reveals every step of the process, from selecting the best materials to achieving flawless finishing.

Why Cotton T-Shirt Manufacturing Is So Popular

Cotton t-shirts dominate casual wear markets worldwide. According to industry reports, the global t-shirt market is expected to grow steadily over the next decade, driven by demand for sustainable, comfortable, and versatile clothing. Cotton, being a natural fiber, offers breathability and softness unmatched by many synthetic fabrics.

Step-by-Step Cotton T-Shirt Manufacturing Process

1. Cotton T-Shirt Manufacturing: Material Selection

The quality of your t-shirt starts with fabric selection. Choose 100% combed cotton for premium lines or organic cotton for eco-conscious customers. Combed cotton undergoes an extra process where short fibers and impurities are removed, making the fabric softer and more durable.

Tip: Check the fabric weight (measured in GSM – grams per square meter). A standard premium t-shirt ranges from 160–200 GSM. Heavier fabric offers a thicker, more luxurious feel.

2. Fabric Knitting

Circular knitting machines are commonly used to produce jersey knit fabric. Jersey knit is soft, stretches well, and is perfect for everyday wear. The knitting process affects how the fabric will drape and feel on the body.

Sub-Steps:

- Load cotton yarn onto the knitting machine

- Knit the yarn into continuous rolls of fabric

- Inspect the rolls for defects before dyeing or cutting

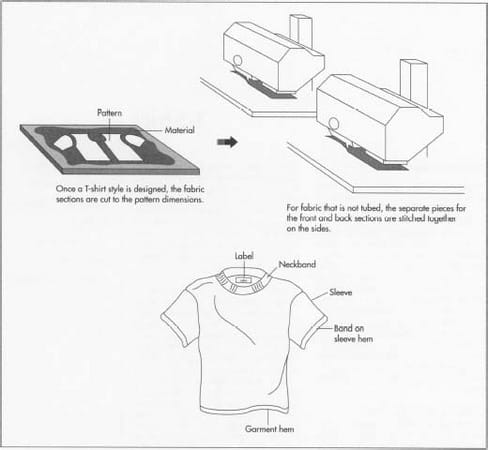

3. Cutting & Pattern Making

In cotton t-shirt manufacturing, precision is crucial. Patterns are made for each size and style (crew neck, V-neck, oversized, fitted). Automated cutting machines or laser cutters ensure every panel is identical.

Sub-Steps:

- Lay the fabric flat in layers

- Place the cutting pattern on top

- Cut using automated or laser equipment

- Group the cut pieces by size and style

4. Stitching

Once the fabric pieces are ready, they move to the stitching line. Overlock machines join the panels, and coverstitch machines finish the hems and neckline.

Sub-Steps:

- Stitch shoulder seams

- Attach sleeves to the body

- Sew side seams

- Finish hems and neckline

- Add reinforcements to stress points

5. Finishing

The final stage in cotton t-shirt manufacturing ensures the product looks and feels perfect for the customer.

Sub-Steps:

- Wash the t-shirts to soften the fabric

- Press with steam irons for a smooth finish

- Add brand labels, size tags, and care instructions

- Package for retail or wholesale distribution

Cost Considerations in Cotton T-Shirt Manufacturing

The cost per t-shirt depends on:

- Fabric quality (organic, combed, blended)

- Labor costs in your manufacturing region

- Order volume (larger batches reduce cost per unit)

- Printing/embroidery for designs or branding

Quality Control Tips

- Inspect fabric for flaws before cutting

- Test stitching durability

- Measure shrinkage after washing

- Check color consistency after dyeing

Frequently Asked Questions (FAQs)

Q: How long does cotton t-shirt manufacturing take?

A: For bulk orders, production can take anywhere from 2–6 weeks depending on order size and complexity.

Q: What is the most durable cotton fabric for t-shirts?

A: Combed cotton and organic cotton are both durable and soft. For workwear or heavy-duty use, opt for a higher GSM fabric.

Q: Can I use blends instead of 100% cotton?

A: Yes, cotton-poly blends can reduce costs and improve wrinkle resistance, but they are less breathable than pure cotton.

Pro Tip: Always create a small sample batch first. This allows you to test for shrinkage, stitching strength, and fabric quality before moving to mass production.